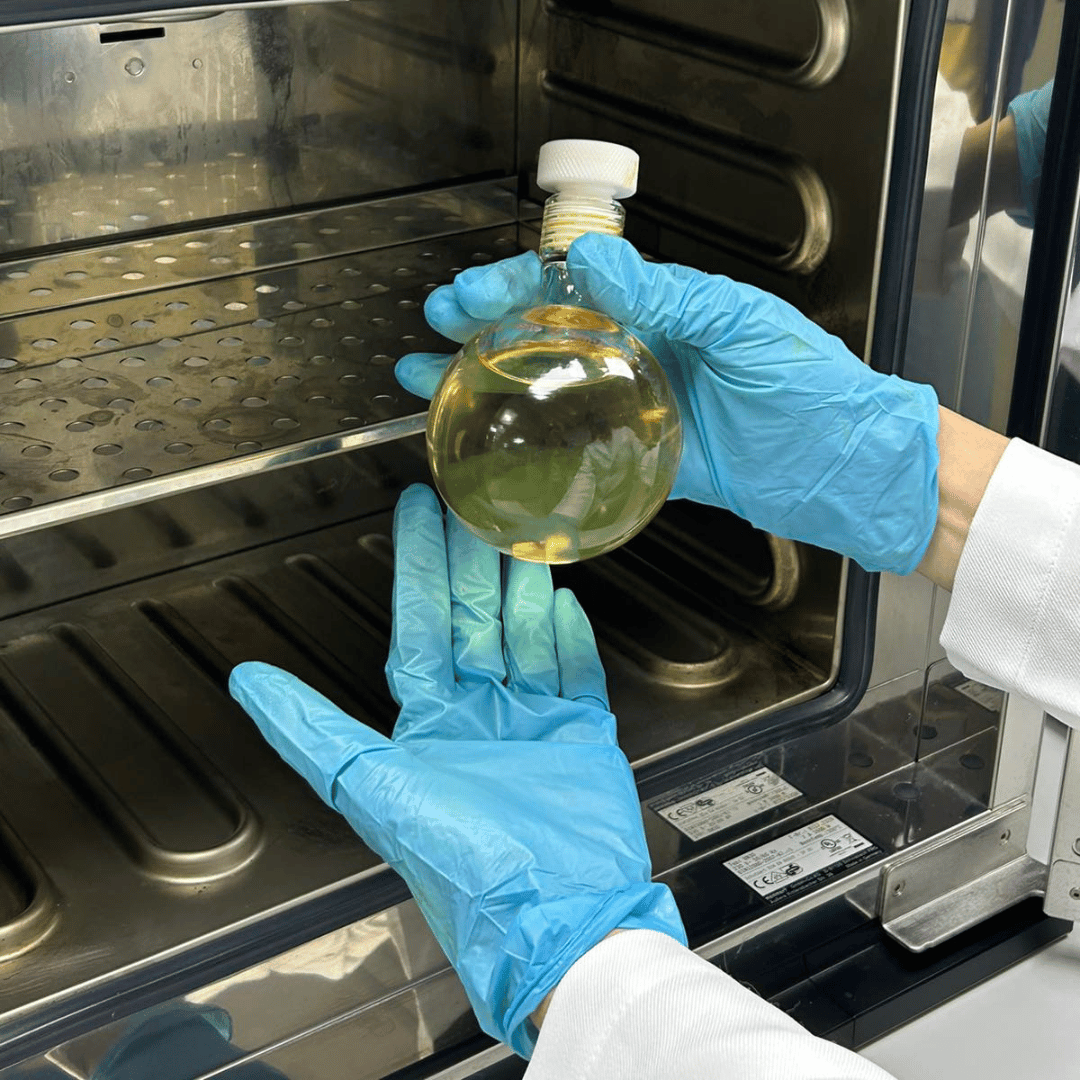

Our laboratory specializes in a comprehensive range of tests, utilizing advanced procedures and equipment to assess the health and integrity of transformer insulation.

At the forefront of quality and reliability, Westco offers an extensive range of testing services that include: dissolved gas analysis, dielectric breakdown voltage testing, power factor test, furan analysis, corrosive sulfur test, moisture content test and more.

See our lab's capabilities

Dissolved Gas Analysis (ASTM D3612)

The DGA test detects various gases that are dissolved in the insulating oil. The amount of gasses is measured in parts per million (PPM) and will indicate the types of stress wether thermal or electrical, that occur within the transformer.

Furan Analysis HPLC (ASTM D5837)

This test method has been used to successfully test for furanic compounds in mineral insulating oil, silicone fluid, high fire point electrical insulating oils of mineral origin, askarels, and perchloroethylene-based dielectric fluids.

Moisture Content (ASTM D1533)

Even in minute quantites, water or moisture is extremely dangerous power equipment. Moisture accelerates the deterrioration of insulating oil and paper insulation.

Neutralization Acid Number (ASTM D664)

ASTM D664 is a standardized procedure for assessing the acid number of petroleum products, lubricants, biodiesel, and biodiesel mixtures via potentiometric titration.

Interfacial Tension (ASTM D971)

The IFT or Interfacial Tension measures the tension between water and oil at the point of interface. The IFT test determines the presence of oil decay products and soluble contaminants from solid insulating materials.

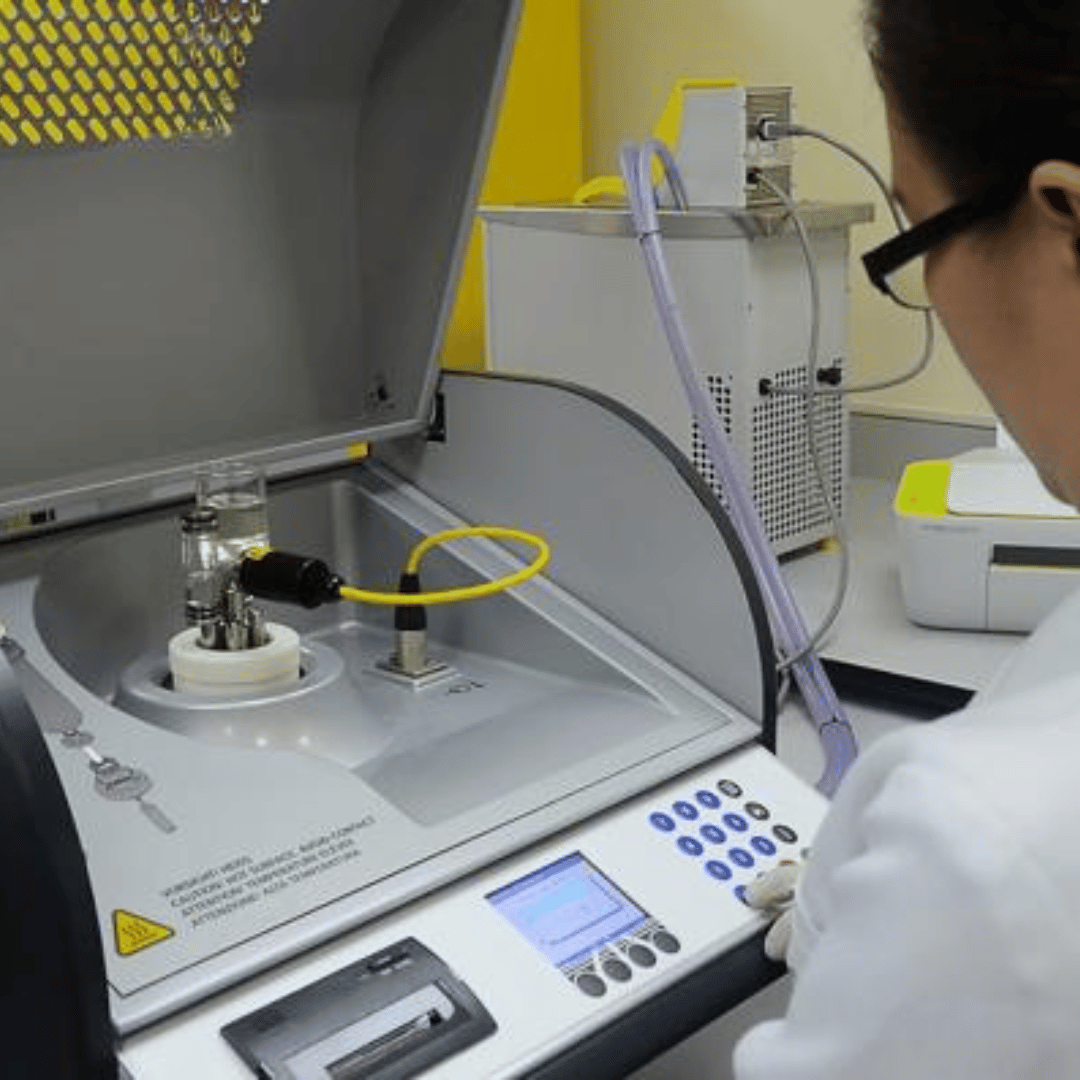

Dielectric Breakdown Voltage (ASTM D1816)

The DBV Test determines the strength of an insulating oils sample to withstand electrical voltage without failure. Contaminants such as moisture or particulars can compromise the insulation properties of oil.

Power Factor / Dissipation Factor (ASTM D924)

The Oil Power Factor Test measures the leakage current through an insulating oil. The test also determines dielectric losses of the oil or the energy that it dissipated as heat insulating materials.

Color (ASTM 1500)

ASTM D1500 is a standardized color scale and testing methodology for assessing the color of petroleum products, particularly transformer oil.

Visual Examination (ASTM D1500)

The transformer oil color is determined by passing a beam of light to determine transparency and identify foreign contaminants. Contaminated oil shows poor transparency or visual evidence of foreign particles.

Specific Resistance (ASTM D1169)

ASTM D1169 is the standard test method for measuring the specific resistance (resistivity) of electrical insulating oils. This test is crucial for evaluating the insulating properties of transformer oil, ensuring optimal performance and longevity of transformers.

Corrosive Sulfur Test (ASTM D1275B)

New and in-service mineral insulating oils may contain substances that cause corrosion under certain condition of use.

The primary purpose of the test is to determine if any corrosive sulfur compounds in the oil will react with the copper strip.

Acid Number ASTM D664

Specific Gravity

Oxidation Inhibitor

Relative Permittivity

Dialect Constant

Conductivity

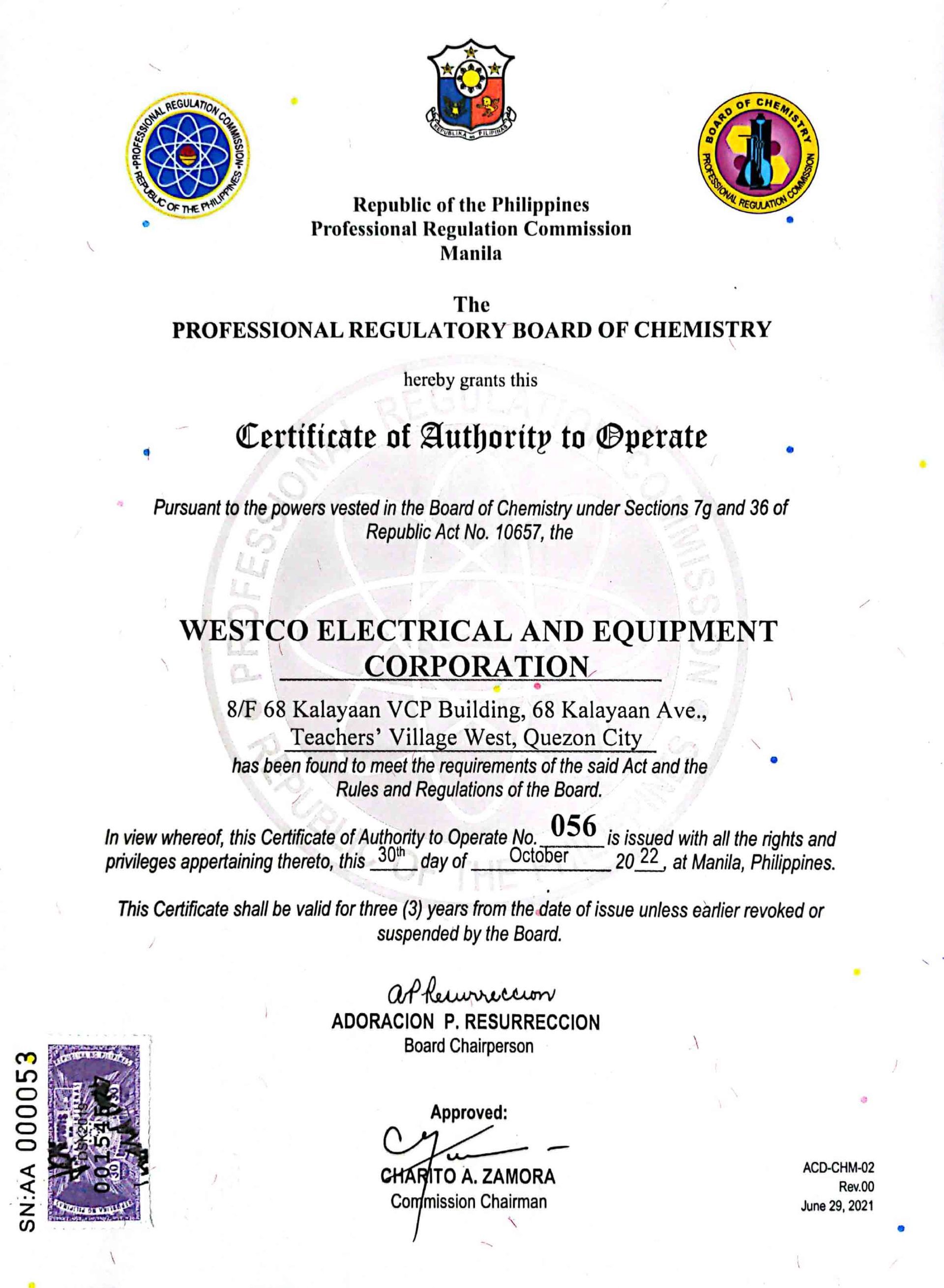

Professional Regulatory Board of Chemistry

Certificate of Authority to Operate