Ensure transformer reliability with Westco’s advanced transformer oil testing services! 👉

Protect and Preserve your Power Transformers with our Insulating Oil Testing Services

Our laboratory specializes in a comprehensive range of tests, utilizing advanced procedures and equipment to assess the health and integrity of transformer insulation.

At the forefront of quality and reliability, Westco offers an extensive range of testing services that include: dissolved gas analysis, dielectric breakdown voltage testing, power factor test, furan analysis, corrosive sulfur test, moisture content test and more.

WESTCO - Your Trusted Partner in Transformer Oil Analysis

Insulating Oil Testing Services

At Westco, we understand the critical role insulating oil plays in maintaining your equipment's reliability and longevity. That's why we offer comprehensive Insulating Oil Testing Services, meticulously designed to ensure your oil is capable of handling the job.

Our in-house laboratory is equipped with state-of-the-art equipment and experts to analyze every aspect of your insulating oil's composition and condition.

With Westco by your side, you gain unparalleled insight into your equipment's performance, enabling you to make informed decisions and prevent costly downtime.

Dissolved Gas Analysis (ASTM D3612)

The DGA test detects various gases that are dissolved in the insulating oil. The amount of gas is measured in parts per million (ppm) and will indicate the types of stress, whether thermal or electrical, that occur within the transformer.

Dielectric Breakdown Voltage Test (ASTM D1816)

The DBV test determines the strength of an insulating oil sample to withstand electrical voltage without failure. Contaminants such as moisture or particulars can compromise the insulation properties of oil.

Power Factor / Dissipation Factor Test (ASTM D924)

The oil power factor test measures the leakage current through an insulating oil. The test also determines dielectric losses of the oil or the energy that is dissipated as heat insulating materials.

Relative Permittivity / Dielectric Constant (ASTM D924)

Relative permittivity is the ratio of the capacitance of a capacitor using that material as a dielectric, compared with a similar capacitor that has vacuum as its dielectric.

SPECIFIC RESISTANCE / RESISTIVITY (ATM D1169)

The resistivity of a liquid is a measure of its electrical insulating properties under conditions comparable to those of the test.

Furan Analysis HPLC (ASTM D5837)

This test method has been used to successfully test for furanic compounds in mineral insulating oil, silicone fluid, high fire point electrical insulating oils of mineral origin, askarels, and perchloroethylene-based dielectric fluids.

Corrosive Sulfur Test (ASTM D1275B)

The primary purpose of the test is to determine if any corrosive sulfur compounds in the oil will react with the copper strip to turn it gray or black.

Corrosive sulfur testing lets you find corrosive sulfur levels early on, so you can take steps to protect dielectric strength and overall performance.

Moisture Content Test (ASTM D1533)

Even in minute quantities, water or moisture is extremely dangerous for power equipment. Moisture accelerates the deterioration of insulating oil and paper insulation.

Power Transformer

Testing Services

- Insulation Power Factor Test

- Exciting Current Test

- Transformer Turns Ratio Test

- Leakage Reactance/ Short Circuit

- Impedance Test

- Insulation Resistance Test with

- Polarization Index

- Winding Resistance Test

- Bushing C1& C2 Test

- Bushing Hot Collar Test

- Sweep Frequency Response Analysis

- Partial Discharge

Why Choose WESTCO?

Westco provides expert power transformer insulating oil testing with a focus on accuracy and reliability. With our state-of-the-art laboratory equipment, dedication to quality, advanced testing methods, and commitment to keeping your power assets operating safely and efficiently.

Westco Insulating Oil Laboratory - 8th flr. 68 Kalayaan Ave., Teachers' Village West, Diliman, Quezon City, Philippines 1101

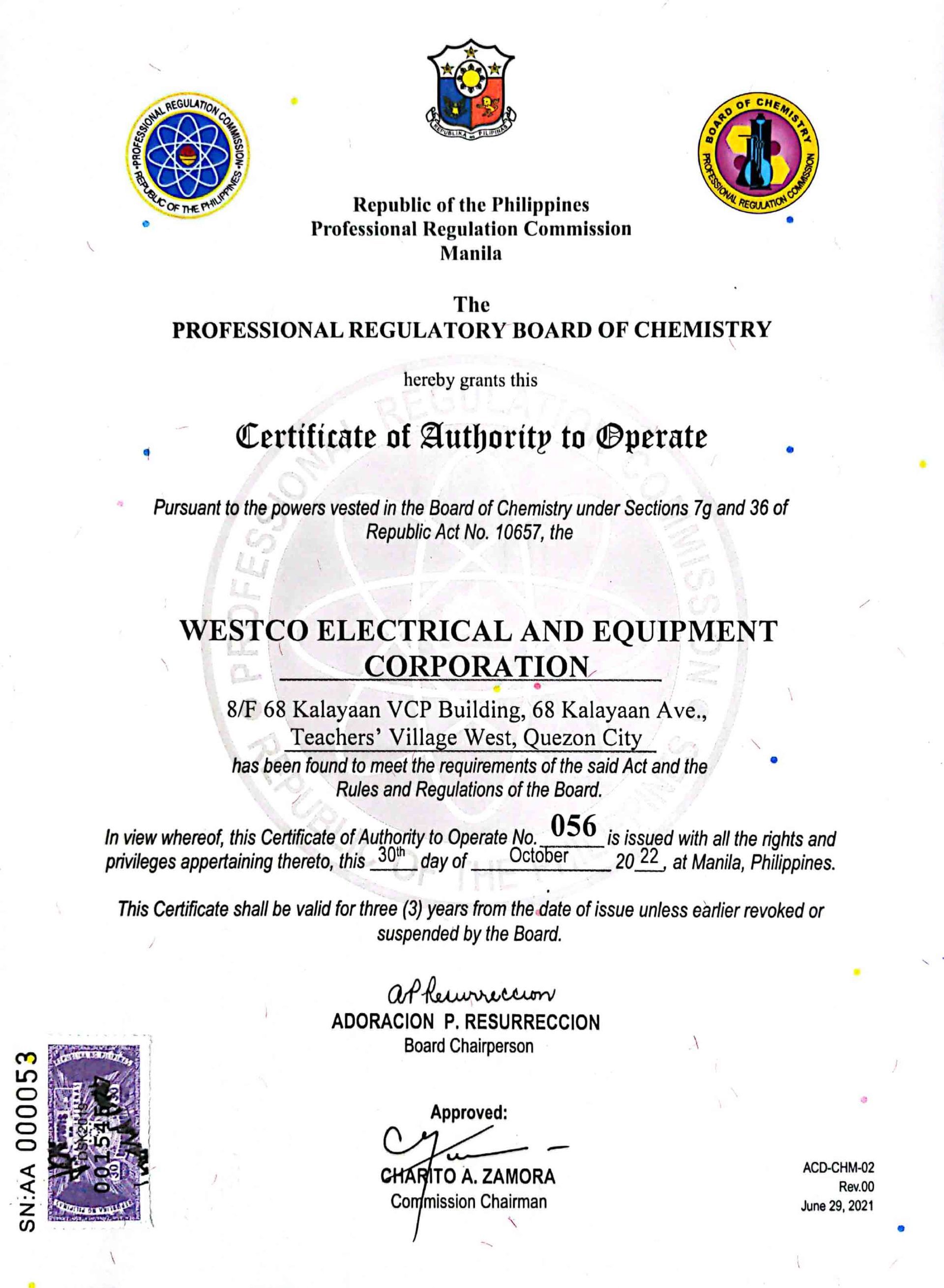

Professional Regulatory Board of Chemistry

Certificate of Authority to Operate